Given how quickly technology advances and becomes outdated, there’s a good reason to develop electronics from materials that will break down and biodegrade when discarded, instead of filling up landfills for centuries. So researchers in Finland found a way to make functional fiber optics from wood-based fibers, that, when disposed of, will break down all on its own.

Fiber optic cables are quite possibly the unsung heroes of the modern digital world. Unlike wires made of metal that carry electrical signals, the cables contain long thin threads of either glass or plastic that transmit pulses of light for miles, connecting data centers, cities, and even continents. Instead of flowing electrons, pulses of light travel down fiber optic cables using a process called total internal reflection where photons bounce off the inner walls of the transparent fibers and remain contained within during their journey from one end to the other.

For data to be transmitted with minimal errors it requires those fibers to be optically perfect, which seems like the exact opposite of anything made from wood. But wood isn’t completely opaque, and depending on its thickness, moisture, and other added materials, photons can still pass through it—as demonstrated by the myriad of wooden lamps available.

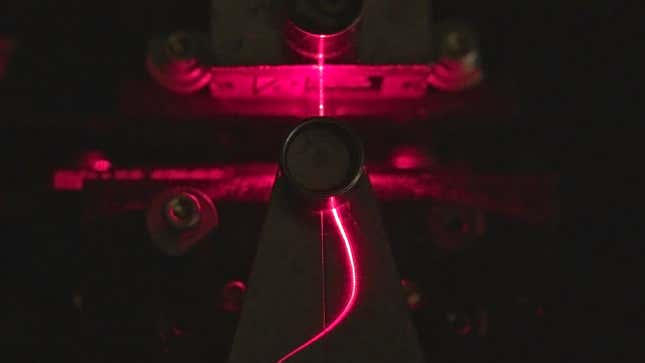

But it’s not like the researchers from the VTT Technical Research Centre of Finland simply yanked a branch off a tree and attempted to send pulses of light down its length. The fiber optic cables its researchers developed are actually made from wood-based cellulose: the structural material that allows plants to stand upright. The manufacturing process involves treating it with salt-based ionic solvents and then wrapping it with an outer layer made of cellulose acetate which has a lower index of refraction than the core does. Consequently, as with fiber optic cables made from glass or plastic, photons bounce around inside and remain trapped.

However, it will be a long time before the discovery replaces the traditional materials used to make fiber optic cables. Its ability to transmit pulses of light pales in comparison to glass or plastic, but it does exhibit unique characteristics that make it useful for other applications while the researchers improve its performance. Being made of wood fibers, it’s able to absorb water, and that affects its ability to transmit light, which can be measured. So an immediate application could be as a moisture sensor for structures made of wood or other materials that don’t play well with water.