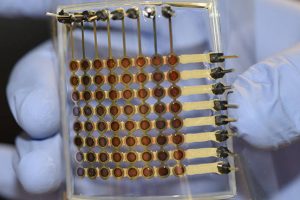

A student engineering team from the University of Illinois at Urbana-Champaign won a design competition for the cab, and was on-hand to watched it being printed using carbon fibre-reinforced ABS (acrylonitrile butadiene styrene).

The cab is part of US Project AME (additive manufactured excavator), a demonstration of facilities at the Oak Ridge National Laboratory.

Also to be printed are the excavator’s boom, using newly-developed large-scale free-form steel additive manufacturing technique, and a heat exchanger for its engine.

Alongside the University of Illinois, academic partners include:

- Georgia Tech – Designs for 3D printable steel boom, stick and bucket

- University of Minnesota Design for aluminium-powder bed 3D-printed oil cooler

The excavator is a collaboration between:

- Association of Equipment Manufacturers

- National Fluid Power Association

- Center for Compact and Efficient Fluid Power

- Oak Ridge National Laboratory

- National Science Foundation

Support came from the US Government’s Office of Energy Efficiency and Renewable Energy

Photo credit: Rachel Brooks ORNL

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News