Today 3D print giant Stratasys announced a bold new strategy focused on industry that will no doubt have a significant effect on manufacturing in the future.

The company has been pursuing a “vertical” strategy in recent years that has been reasonably successful. This strategy is driven by the years of challenge selling 3D printing gear to industry. I’m not saying their efforts up to now have been unsuccessful, but rather that they see enormously larger opportunities for industry to take advantage of their 3D printing technologies.

However, many industries has been reluctant to adopt 3D printing due to cost, unawareness, and most importantly, a lack of an ability to understand how to properly leverage the technology for their advantage. In other words, companies largely don’t know how to beneficially use 3D printing.

Thus Stratasys has been organizing their company around specific vertical industries that they see should have great benefits by using 3D printing, including aerospace, automotive and healthcare. These vertical divisions have been providing startup, educational and consulting services to those industries in successful attempts to get them more familiar with 3D printing technologies.

But today’s announcement goes far deeper.

They intend on providing ways to very deeply integrate with industrial manufacturing processes. They’ve announced new equipment concepts, software, systems and the intent to organize their solutions around industrial processes from now going forward.

Thus while they may sell 3D printers, they’re positioning as a manufacturing solutions company in which 3D technology is only part of the answer. And this is the correct answer: manufacturers don’t buy 3D printers because they are 3D printers. They (should) buy them because they are part of an efficient and effective manufacturing workflow.

To do this, they’ve developed a couple of entirely new 3D printing concepts that eliminate several manufacturing barriers. These concepts achieve the key goals of:

- Producing parts much more quickly and efficiently

- Producing much larger parts

- Producing parts with repeatability suitable for manufacturing needs

- How does this work? There are two new machine concepts. We will cover them each in a bit more detail in upcoming posts, but for now this is a summary.

First, there is the “Infinite Build 3D Demonstrator”. This is NOT a product. It’s a concept demonstration device that shows to all, especially industry, that Stratasys has been able to achieve the goals listed above. It has a very large print area of approximately 1m square. (Why am I not mentioning the Z-axis? Read on!)

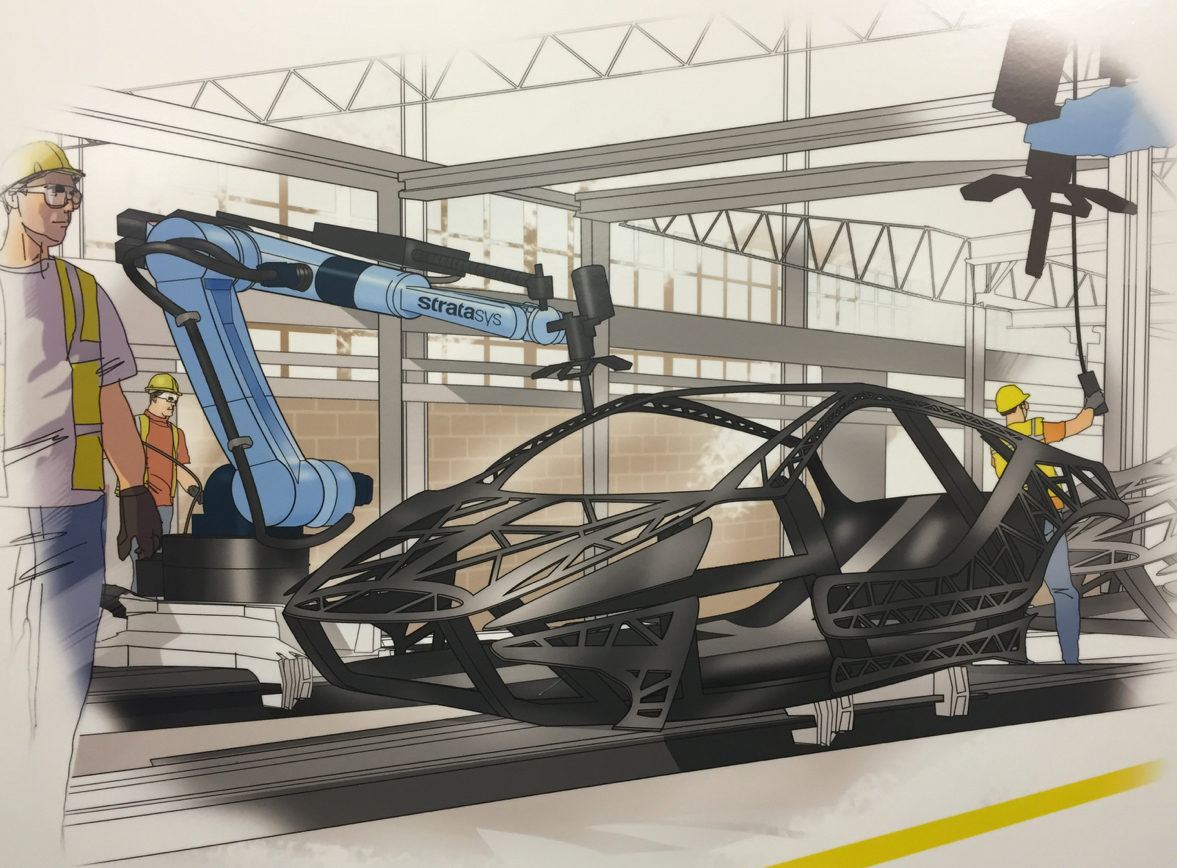

The “IB3D” Demonstrator is a very peculiar and large format 3D printer whose Z-axis is tilted 90 degrees: This machine prints SIDEWAYS! And it has an open end enabling the machine to print INFINITELY LONG OBJECTS, should you be able to feed it enough raw material.

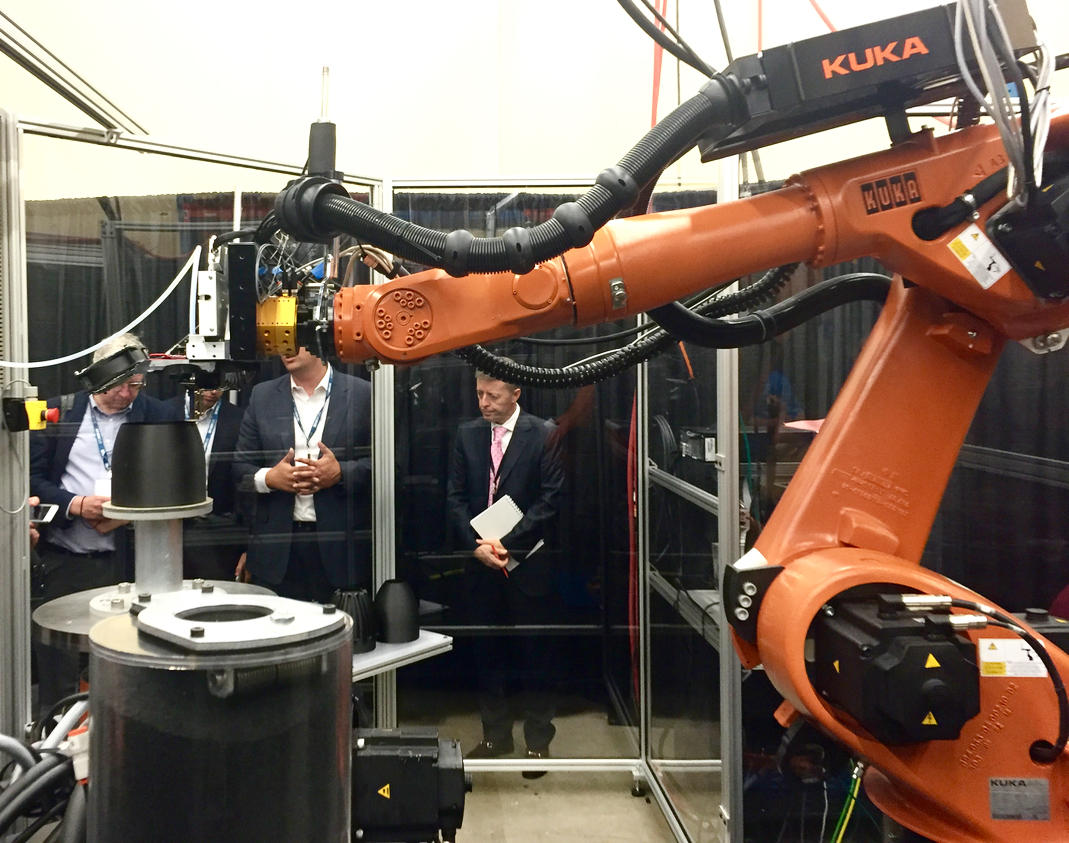

The second machine concept is the “Robotic Composite 3D Demonstrator”. It’s essentially an 8-axis industrial robot arm with an FDM extrusion head on the end of the arm. While this concept has been attempted previously on an experimental basis by others, it seems that Stratasys has developed a system that is (or soon will be) capable of integrating into a production manufacturing environment by providing high-quality parts with repeatability.

The interesting part of the “RC3D” Demonstrator is that it does not print in standard layers as all other 3D printers do. It can move in extremely complex motions (due to the 8-axis robot) and thus print any complex geometry WITHOUT THE NEED FOR SUPPORT MATERIAL. If there’s an “unsupported” portion of the print, it simply tips the print around so that it is no longer unsupported!

But again, these are concept demonstrators; they are NOT products. Stratasys has much work to do to transform them into product-like units, but it seems they’ve overcome most of the heavy-lift technology problems.

I’m not sure these concepts will actually BE products in the truest sense, as they are so large that I suspect they may in the end be universally customized to match the needs of the buyer. They’ll have different combinations of toolheads, different abilities to print materials and more.

Finally, Stratasys announced a relationship with Siemens to develop the very complex software systems to drive these two very different 3D printing concepts, and do so in a way that deeply integrates with related industrial processes.

Stratasys seems very focused on significantly enhancing the ability for manufacturers to take advantage of 3D technology by literally changing it to be much more compatible with the needs of manufacturers.

If industry is not coming to the 3D printer, then the 3D printer shall go to the industry. And that’s exactly what they are doing.