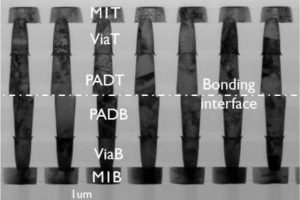

“This opens up the prospect of using tantalum in layers just a few nanometers thick as the liner for interconnect wiring in the complex geometries of next-generation electronic chips,” said the University, which worked with German chemicals giant BASF on the project.

Tantalum has previously been deposited by techniques such as sputtering or with plasma, none of which can uniformly coat complex 3D structures with the tolerance that Wayne State is reporting – better than 0.1nm.

“There exists a high demand for strongly-reducing co-reagents capable of enabling atomic layer deposition of electro-positive metal films like tantalum) from metal-organic precursors,” said Joseph Peter Klesko from Wayne State University. “Developing new chemistry, with novel mechanistic approaches for the reduction of these precursors, is critical for the use of these metal films in next-generation devices.”

This is one of a number of thin film innovations presented this week at the 16th International Conference on Atomic Layer Deposition (ALD 2016) in Dublin.

Today, ALD is primarily used for depositing thin film dielectrics. However, there is increasing need to deposit ultra-thin metal layers as part of the ever-finer mesh of three-dimensional wiring over silicon die.

Also at ALD2016, the same Wayne State team plus Marissa Kerrigan will announce a new process for cobalt metal that selectively coats only metal surfaces but not the chip’s insulating materials.

“The Wayne State processes for tantalum and cobalt are significant steps forward in controlled growth of ultra-thin metals,” said conference chair, Dr Simon Elliott of Ireland’s Tyndall National Institute. “Strong growth is projected for area-selective deposition: in the near future, it will allow higher-precision patterning of semiconductor chips, and in the longer term it will be an enabler for manufacturing nano-structured materials on demand.”

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News