Newly-invented plastic from biomass degrades after use

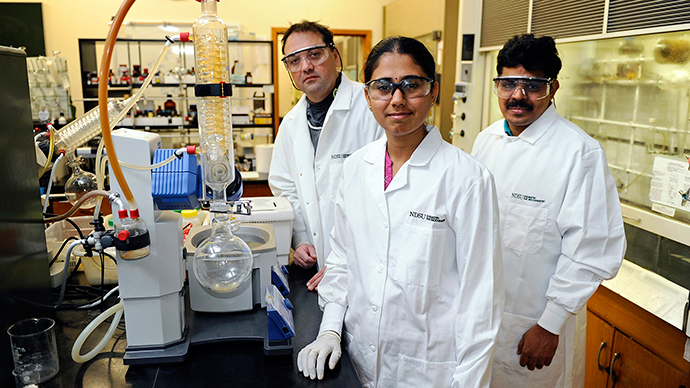

Researchers from North Dakota State University (NDSU) have discovered a way to make a new type of plastic that breaks down and degrades when exposed to a specific kind of light, which reduces it back to molecules.

The scientists, whose work has been published in Angewandte Chemie, used fructose to create a molecular solution, which they turned into plastic.

They exposed the polymer to ultraviolet light at a certain wavelength for three hours, which reduced the plastic back to molecules.

“Real sustainability involves breaking it back into building blocks. We have shown that we can break it down into the building blocks and re-make the polymer,” said Mukund Sibi, one of the key researchers on the team and professor at NDSU.

The method is important because plastics as we use them today take hundreds of years to decay and remain in the soil and water for centuries polluting the environment. When burnt they release dioxins which are known to be toxic.

Plastics are used in almost everything surrounding us, from electronics to packaging. Once discarded, they lie for hundreds of years in the oceans and landfill sites.

But by using biomass to make polymers and plastic composites, they become a biodegradable renewable source.

“This cradle to cradle approach to create a plastic which can be degraded easily offers scientific potential for eventual products that could lessen dependence on fossil fuels and decrease the amount of raw materials needed,” said Dr Dean Webster, professor at NDSU’s department of coatings and polymeric materials.

The scientists say that further research is needed to evaluate the strength and durability of plastics made from biomass before they can become commercial.

Over the next couple of years the team is planning to work with plastics used in cars and electronics as well as other items in order to try and perfect the process.