Remember a few days ago we saw an abandoned place full of optical sights? Now we have optical sights for guns again but this time its not abandoned and they are not made yet. We will see how those are being manufactured and assembled. Might be pretty interesting inside, thanks to Aslan who has visited a highly secured production line of this Russian factory specializing in the long range aiming optics. Normal people are not allowed there with a camera but he went and made those photos! So let’s see, that should be interesting:

This factory is situated on the closed circuit territory belonging to an army factory. The soldiers on the checkpoint didn’t want him even to take the camera inside, but he managed to come thru the security.

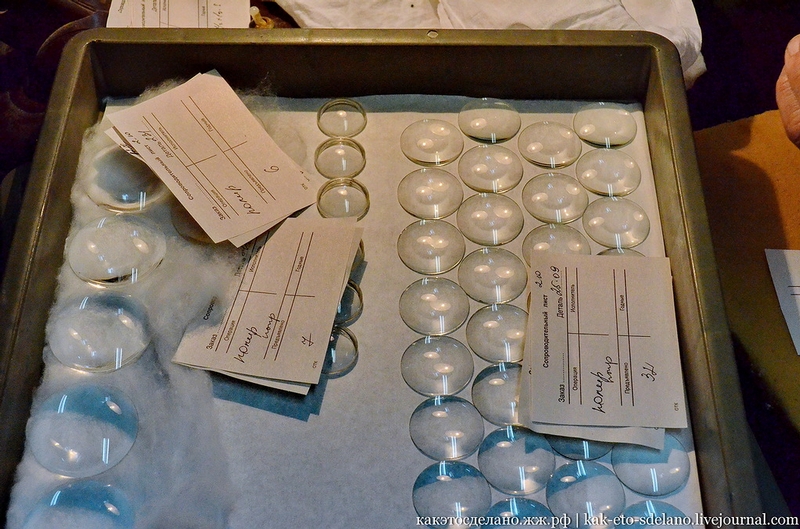

So let’s get down to the business. This is a glass cube. Those glass cubes are used to produce the lens – the essential part of the sight.

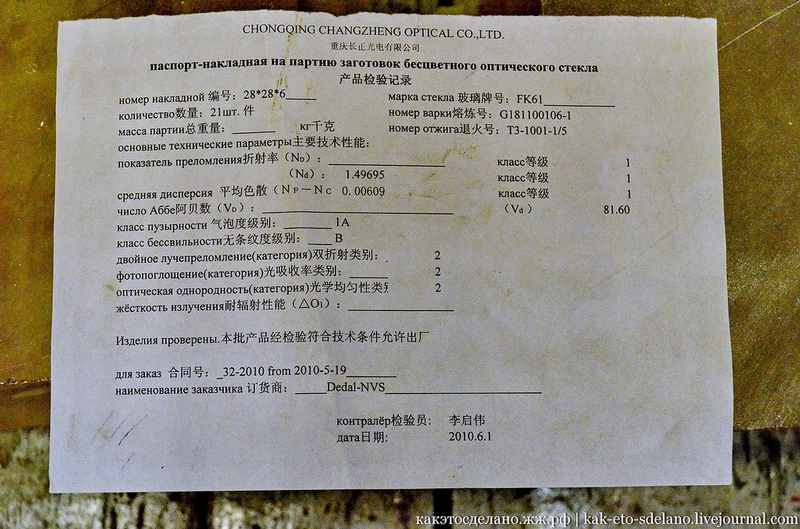

Some of them arrive from China. Workers on the plant told Aslan that before the quality of Chinese glass was pretty bad, but lately it got better.

Why do you use Chinese glass when we have Russian glass, asked Aslan.

Because Russian glass is three times more expensive, was the reply. Of course it’s not a regular glass but some specially chemically enhanced glass. Russian glass comes in this large cubes you see on the photo.

So they cut pieces out the cubes – like this.

But Chinese partners send them ready premade parts like this on the photo.

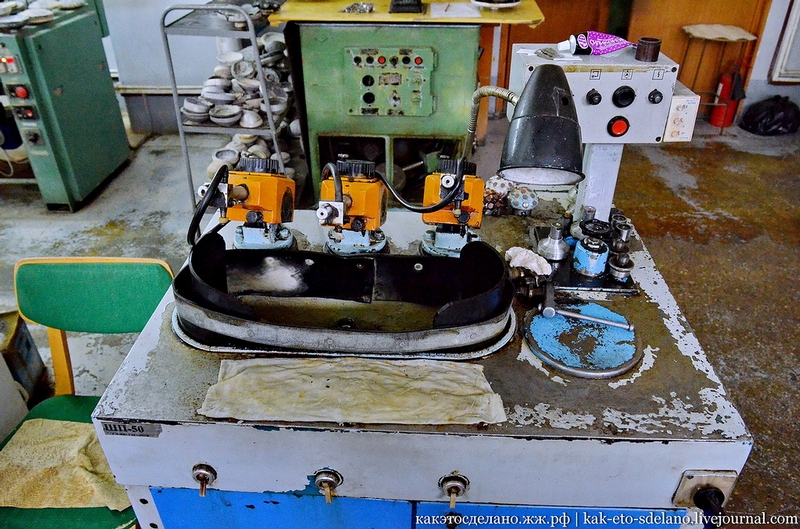

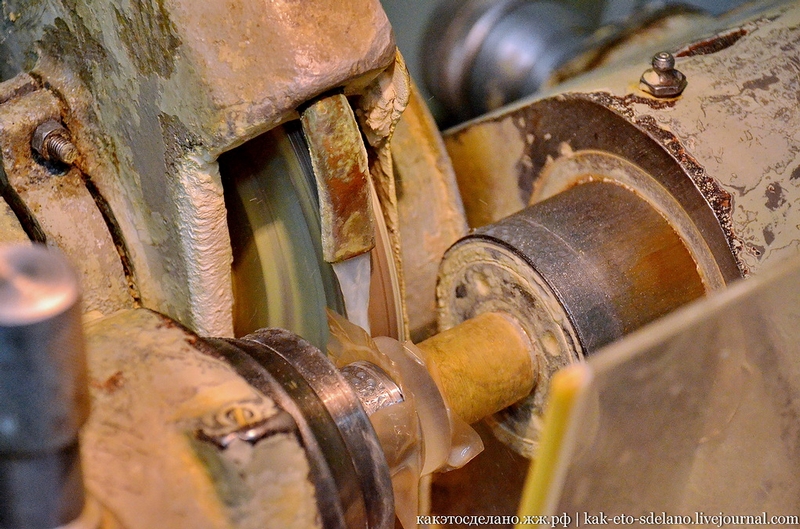

So then those pieces go to polishing machines. Those machines are over forty years old but work pretty ok.

It’s being put inside the machine.

And this gadget is going to polish it.

While it is polishing the special fluids being fed to make it wet.

The guy shows how the gadget polishes the lens.

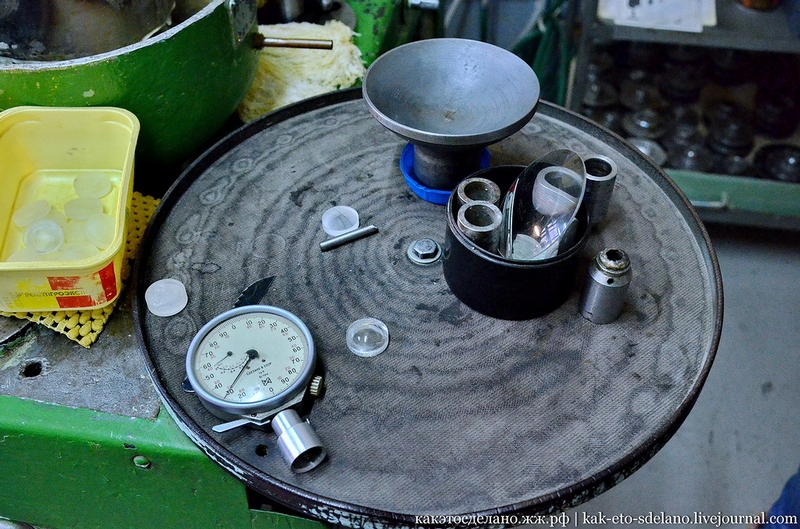

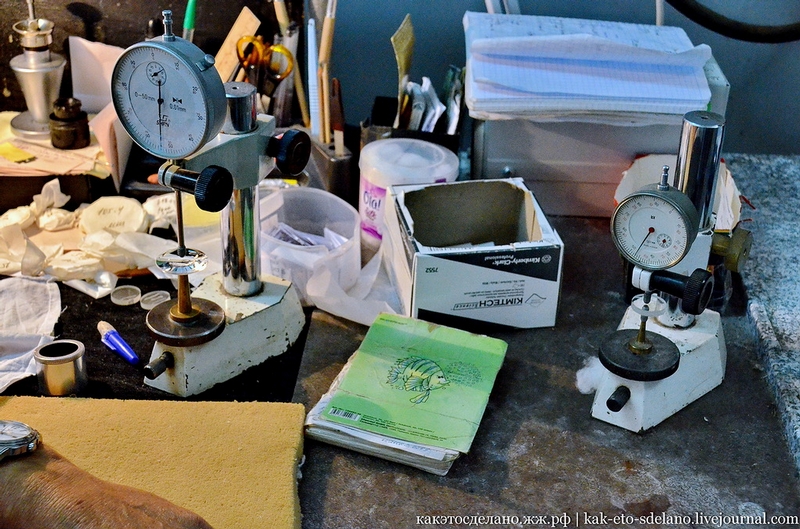

Then this device is used to measure its curvature.

If it’s not enough the polishing continues.

Those are different sizes of gadgets for different sizes of lens.

Those lens look like candies says Aslan.

And this machine is used to cut that huge cubes of glass.

Those are the cubes cut in parts. Slices of glass.

However they need to be like that first.

A few steps of polishing. Still not ready yet.

This machine is used to process that glass slices they get from the glass cubes.

On each glass bar he showed in hand they glue two round pieces – they act like the limiter for grinding. So after grinding by the borders of those circles the glass bar turns into glass cylinder. Which is later cut into flat lens.

After initial polishing lens come here.

With high temperature resin its being glued to this thing.

And inserted into another thing.

Then the first thing pulled off.

And lens become glued to the second thing. Funny isn’t it.

Then some hammering.

And those spheres with lens go into the oven. And baked till ready.

And baked till ready.

Then a razor used to scrap the excess of resin.

If it’s pretty ok it goes further on.

Here. Aslan says this place impressed him most.

Here are some more polishing machines.

They polish a lot of lens at once.

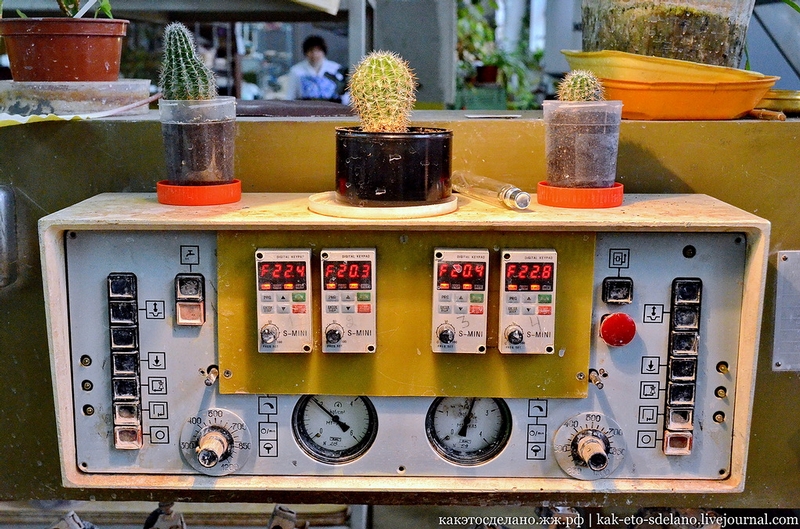

Again with fluids. It takes 1-4 hours to complete.

Each robotic hand polishes one small lens.

And here big lens being polished.

Diamond powedered gadgets massage carefully those lens.

Here is a short video of the process Aslan made.

Those things are made back in 1958.

Then the polished surface going to be covered with special lacquer. Look how shiny they are?

With each step they look more and more awesome.

Then they go to the acetone bath to remove the residues of resin and other stuff.

Being measured again to match the standards.

The lady checks the quality of the lens. It should have any microscopic defects or scratches.

And here is the next step – centering of the lens. Their optical center is being aligned with their geometrical center.

This was an ancient machine too but it got connected to computer and upgraded.

And grind away the milimeters.

So lens are almost ready but the sights are not even started. However the first part of this story is over and if you are interested come back tomorrow or on Sunday to see the second part of how those lens now being assembled into the sights themselves.

Big thanks to Aslan for his trip and photos!

Very exciting.