Cheaper synthetic fluorite could mean lighter, higher-quality lenses in the future

posted Thursday, March 12, 2015 at 1:29 PM EDT

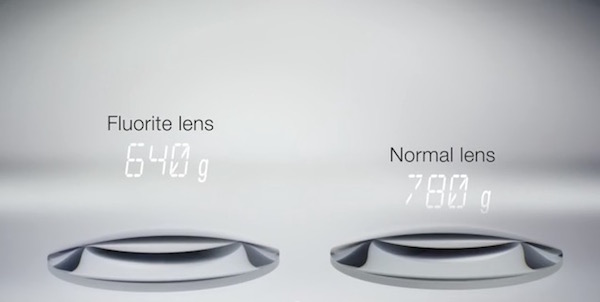

Fluorite (not to be confused with fluorine) has become an interesting player in the optics market. The mineral form of calcium fluoride, ultra-high-grade fluorite is used to create low-dispersion optical elements that improve image quality by reducing the chromatic aberration and color fringing that plague traditional, glass-based optics. Fluorite lenses also enjoy a roughly 10% weight advantage compared to their traditional counterparts.

The problem with high-grade fluorite is cost. Mined almost exclusively in China, there’s a natural monopoly of sorts on high-purity deposits of the mineral, leaving lens manufacturers little to do but pay up if they want the optical properties of the mineral.

Iwatani Corp. is looking to change that. Headquartered in Osaka, Japan, Iwatani is developing a means to synthesize large quantities of high-purity fluorite in hopes it can become a less expensive alternative for lens manufacturers.

But it’s not an easy task. The minimum purity needed for application in optical elements is 99.95 percent. At that purity, fluorite sells for roughly $3.75 per pound -- anything below sells for pennies.

Most interesting about this development is how the machinery and synthesis process came to fruition for Iwatani. Explained by Nakajima to Japan Times, Iwatani originally developed the machinery for recycling perfluorocarbon (PFC) gas, an ozone-harming byproduct of semiconductor manufacturing.

After the machines safely decompose the PFC gas with heat and react the resulting hydrogen fluoride with calcium-based chemicals, calcium fluoride (again, also known as fluorite) is produced as a byproduct. The problem is that the purity of this byproduct is only 90 percent, a far cry from the minimum 99.95 percent purity required for optical applications.

To fix this, Iwatani brought together an all-star team that included limestone producer Uedalime Manufacturing Co. (site in Japanese) and Nagoya Institute of Technology Professor Shinji Yasui.

It took years of trial and error, but with the combined intellectual and capital resources of the three entities, they finally developed a process to synthesize fluorite to a higher purity than its naturally occurring counterpart.

Production costs are still double the cost of mining naturally occurring fluorite, but the team is working to drive down costs. Japan Times reports that the upcoming fiscal year will be used to determine whether they go forward with production or not.

Image credits: Feature image courtesy of Iwatani Corp., lens comparison screenshot from Nikkor Technology video