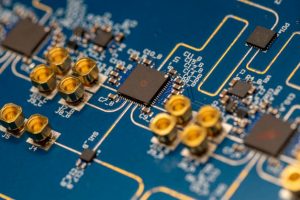

The chip was a 28nm Altera FPGAs cooled by flowing de-ionised water.

With a water inlet temperature of around 20C and 147ml/minute flow, the chip operated at under 24C, compared to 60C fore an air-cooled device.

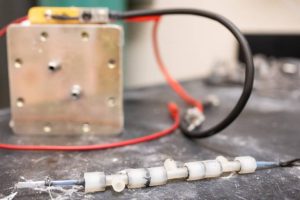

To add liquid cooling, academic Muhannad Bakir, and graduate student Thomas Sarvey removed the heat sink and heat-spreading materials from the backs of stock Altera FPGA chips. They then etched cooling passages into the silicon, incorporating silicon cylinders approximately 100micron in diameter to improve heat transmission into the liquid. A silicon layer was then placed over the flow passages, and ports were attached for the connection of water tubes.

“We have created a real electronic platform to evaluate the benefits of liquid cooling versus air cooling,” said Bakir. “This may open the door to stacking multiple chips, potentially multiple FPGA chips or FPGA chips with other chips that are high in power consumption.”

FPGAs were chosen because they are common, and they are used by the military – DARPA is providing some project funding. The technique could equally apply to CPUs, GPUs and power amplifiers, Bakir said.

In a separate research project, Bakir’s group has fabricated copper vias through the silicon heat transfer columns that could carry signals between chips in a stacked array. “By bringing system components closer together, we can reduce interconnect length and that will lead to improvements in bandwidth density and reductions in energy use,” he said.

“Future high-performance semiconductor electronics will be increasingly dominated by thermal budget and ability to remove heat. The embedded microfluidic channels provide an intriguing option to remove heat from future microelectronics systems,” said Arifur Rahman, Altera’s principal investigator for the project.

The work was presented at the IEEE custom integrated circuits conference as ‘Embedded cooling technologies for densely integrated electronic systems’.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News