The next time you buy a piece of mass-produced clothing, check to see if it’s got any details that look like they were done by hand. Those might include elaborate embroidery, painstakingly attached sequins, or buttonholes carefully stitched by a person rather than a machine. If so, there’s a good chance the garment was quite literally homemade, at least in part—and most likely by a woman who was paid a pittance for it.

People think of manufacturing as something that takes place in factories. But a surprising amount occurs in, or next to, people’s homes. These people are called homeworkers, and research suggests they number far into the tens of millions globally—as many as 30 million may be in China alone, for instance.

In the garment industry, while only being a fraction of the total workforce, they are probably making goods for many local and international fashion brands, both large and small. In India, of an estimated 12.5 million homeworkers, more than 3.5 million are likely part of the supply chains for these brands, according to WIEGO, an organization dedicated to studying and advocating for informal workers, and the most authoritative source on the topic.

Homeworkers are among the lowest-paid members of this workforce, often earning less than even factory workers. And most, not by coincidence, are women. That’s because women are usually responsible for childcare, and in the countries where homeworkers are most prevalent, there are often cultural limitations on women working outside the home.

But there’s no single, definitive count of their numbers, or of how many are producing for international companies, because they’re almost always informally employed, and therefore practically invisible.

It’s this invisibility, coupled with the fact that most are poor and disadvantaged to begin with, that make homeworkers one of the global economy’s most vulnerable labor groups. Despite the work they contribute, they generally fall outside the protection of labor laws. They have little to no bargaining power in relation to the contractors who employ them. And while the money they earn is often critical in feeding their families, it’s rarely enough to help them actually escape poverty.

In many ways, they offer a marked example of the complexities surrounding cheap labor in a global economy. And there’s perhaps no industry where that’s clearer than in fashion.

An economic engine

It’s hard to measure just how prevalent homeworking is. Homeworkers are technically a subcategory of all “home-based workers.” Specifically, they are those who work for an employer, rather than being self-employed and selling their goods or services themselves. Frequently they’re subcontracted, meaning a brand will contract a factory to do work, and then the factory will subcontract the work to the homeworker. Census and employment surveys don’t often drill down to that level of specificity, and information can be lost with each level of subcontracting.

But in 2014, WIEGO, which was founded largely in response to this lack of information, released results from the first round of a 10-city, longitudinal study on the global informal economy. Its findings hint at just how many products are made outside of factories.

Extrapolating on previous research by economists, for instance, WIEGO estimates that more than half of all items manufactured in modern India are home-based, which includes people’s actual homes but also small, informal workshops set up beside them. That number sounds astonishingly high—and home-based work may be especially prominent in India—but the situation also appears to be a byproduct of rapid development.

Though India is the world’s fastest growing economy, it hasn’t built up the organized industrial infrastructure of a country such as China. As jobs move away from agricultural work, the country has depended on its informal economy to fill the manufacturing gap. It’s a similar situation to the one driving the informal economy’s growth in Africa, and likely many other countries (pdf) around the world.

Home-based workers, not surprisingly, do all kinds of jobs, including making incense sticks and flower garlands, stitching cushions for airlines, assembling electronics, and even manufacturing airline and automobile parts. But it’s the clothing and textile industries where homeworkers have perhaps grown the most.

Fashion’s hidden workforce

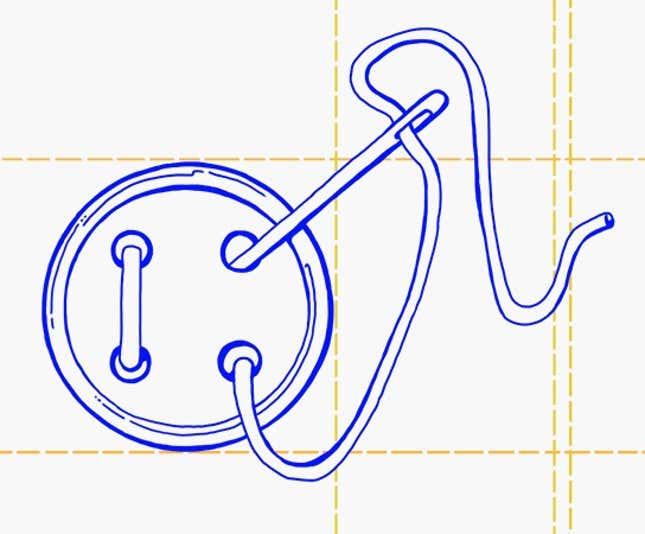

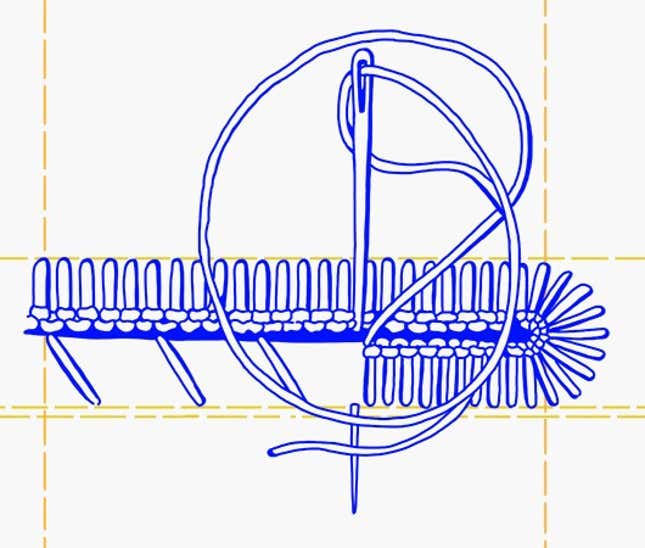

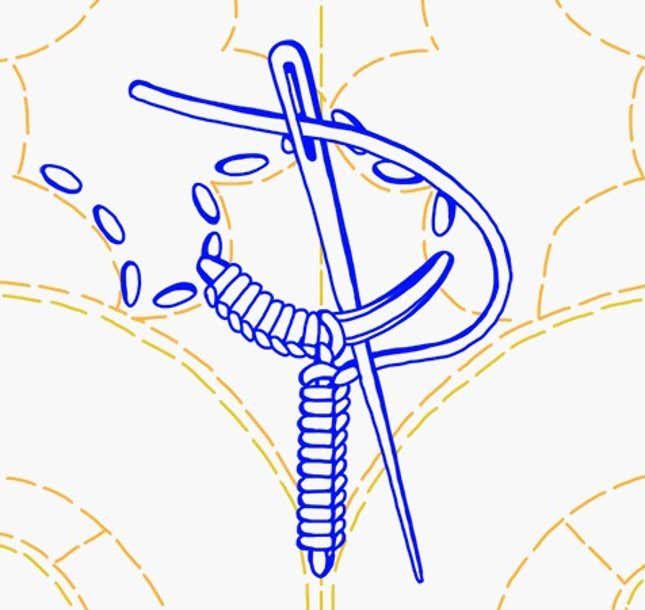

Factories commonly turn to homeworkers for jobs that are labor-intensive and require skilled handwork. In India (which also happens to be one of the few countries where men are a slight majority of homeworkers) that often means embroidery and beadwork, while in countries such as Indonesia and Peru, it could be certain types of weaving or hand-knitting.

But despite homework’s reputation as handicraft, a great deal of it—most according to some sources (pdf, p. 60)—is the kind of industrial work that might otherwise take place in a factory. Typically it will involve one part of the garment assembly line, such as sewing on pre-cut patches with a sewing machine, attaching buttons, or performing low-skill tasks such as snipping loose threads. But WIEGO’s fieldwork has found that homeworkers also assemble whole garments—things such as t-shirts, blouses, and simple dresses.

“You name any brand and they are doing stuff,” says Sanjay Kumar, the director of SEWA Bharat, part of a national trade union that represents 1.9 million informal workers across India, about 25% of whom are homeworkers. ”From Gap to European brands, we have worked with some of these brands in the past and keep getting orders, like Zara.”

In a statement to Quartz, Zara said India makes up less than 5% of the supply chain for Inditex, its parent company. “Most of this sourcing is driven through suppliers and factories and a very small part of it is linked to homeworking,” a spokesperson said. The company didn’t offer details on homeworking in countries besides India, but about 40% of Zara’s manufacturing happens in the Americas and Asia, where homeworking in the garment industry tends to be particularly prevalent.

Despite their best efforts, though, Zara and other brands may not even be able to accurately measure how many homeworkers are in their supply chains, because the subcontracting system keeps homeworkers largely invisible.

If a fashion brand such as Zara places an order with a factory and the factory can’t handle part or all of the work—say it gets inundated with seasonal orders—it will subcontract it out to another factory, or possibly to a homeworker. It’s common for factories to accept jobs even if they know they can’t complete them, especially from large clients, for fear of jeopardizing the relationship.

For a factory to find one of these workers is as simple as having an agent drive up to someone’s village or home in a van, strike an agreement, and then handle the deliveries back and forth. This arrangement means homeworkers usually don’t even know which factories they’re producing for, or whether the clothes are for local markets or export. In a report (pdf) by two researchers in Bangladesh for the Solidarity Center, a workers’ rights group allied with the AFL-CIO union federation in the US, not one of the workers interviewed knew which factory had contracted them.

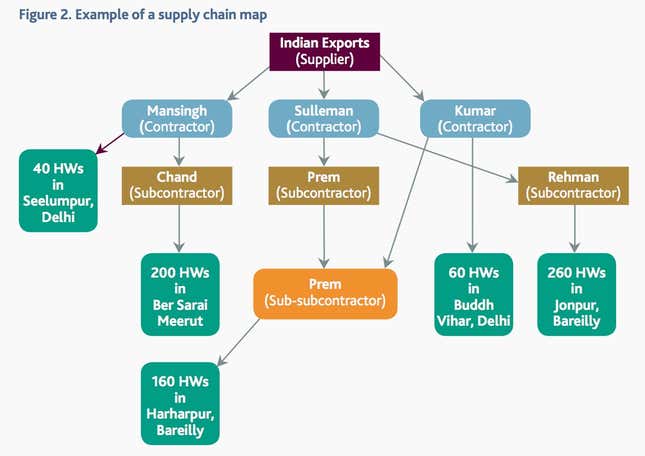

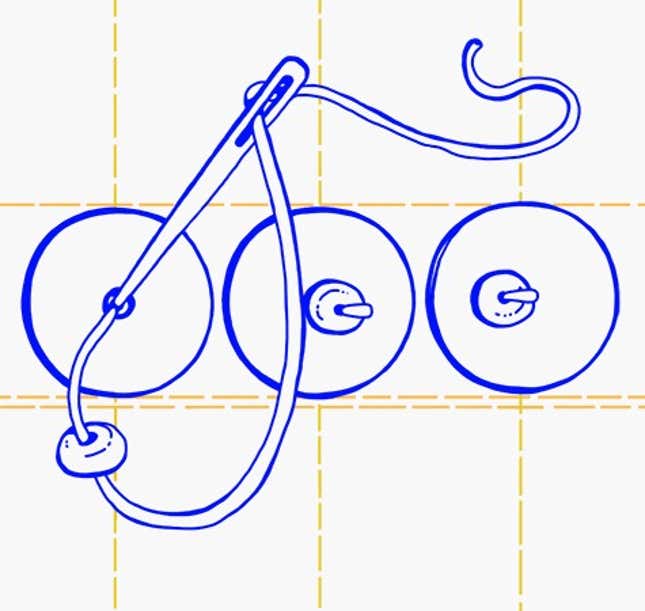

Workers can also be at the end of a series of subcontracts, removing them several steps from the brands they’re actually producing for. To show just how diffuse this supply chain can become, the Ethical Trading Initiative (ETI), an alliance of companies and organizations that advocates for workers, created this example map in a guide for retailers (pdf). The “HWs” in the map refer to homeworkers.

Factories understandably don’t want the brands paying them to know when they’re subcontracting work. It’s the same practice that allowed many brands to say truthfully that they weren’t aware their garments were being made at the Rana Plaza factory in Bangladesh, which collapsed and killed at least 1,134 people in 2013.

As it happens, Bangladesh is one country where the number of homeworkers may be declining (pdf), as the garment-dependent country rapidly builds factories to meet booming demand. Nonetheless, their numbers may still be “huge,” as a report by ActionAid, an international organization dedicated to fighting poverty, put it.

Zara is just one of a number of fashion companies sourcing from these regions, and many, such as H&M, produce a much larger share of their clothes there. The ETI has worked with international labels such as Gap, Primark, and Marks & Spencer (pdf) on identifying and managing homeworkers in their supply chains, and there are undoubtedly countless other brands that source from homeworkers, too. Quartz contacted Primark and Gap for this story, but neither offered any comment or additional information.

Edward Hertzman, co-owner of the trade publication Sourcing Journal, says homeworkers are a sensitive topic. In his experience, which has focused mostly on menswear—a category where homeworkers are less prevalent—they haven’t been a major part of supply chains. But he admits that everyone involved wants to keep the subject quiet.

“I don’t think any company would openly acknowledge or want this to be the case, because if it’s outside of the factory, they can’t control it,” he tells Quartz. “And if they did know it, they would be unhappy about it.”

Clearly it happens anyway. WIEGO’s estimate of how many homeworkers in India produce for local and international brands may even be conservative. Its research suggests that around 45% of the country’s 37.5 million home-based workers make clothes or textiles, and about 33% of those are subcontracted homeworkers. But the share that are subcontracted comes from 1999, the last time the Indian government’s National Sample Survey asked the right questions to allow WIEGO to come up with an estimate.

In WIEGO’s own survey of three cities—Lahore, Pakistan; Ahmedabad, India; and Bangkok, Thailand—conducted from April 2012 to April 2013 for the first round of its longitudinal study—it found that 71% of home-based workers were subcontracted homeworkers. In Ahmedabad in particular, all of the workers surveyed were subcontracted.

Malti’s bed

For a company to have homeworkers involved in its production isn’t a problem in itself. Many women choose homework, and report that they like being able to earn an income while caring for their families. These jobs provide wages that are frequently critical to keeping them and their families out of extreme poverty. (WIEGO has found that homeworkers are more likely to be poor than those who work outside the home.)

Malti is a 40-year-old homeworker who lives with her four children in the Nand Nagri neighborhood of north Delhi. Two years ago, her husband passed away, leaving her the sole breadwinner until two of her sons quit their studies and took up odd jobs. The family lives in a single-room home with one double bed, which her three teenage sons sleep on at night. Malti and her 11-year-old daughter sleep on the floor. During the day, that bed serves as Malti’s work station. It’s where she does embroidery and makes accessories for brands such as Gap and Zara.

The reason she knows the brands she’s producing for is because she’s part of a unique company called Ruaab SEWA, whose 750 shareholders are the homeworkers who also produce for it. SEWA Delhi, the trade union, established it in 2010 as a way for its members to contract directly with international brands.

“We formed the company to facilitate the process of bringing [our homeworkers] together as producers, as artisans, so that they could collectively bargain with the market,” Kumar says. “When you are directly dealing as an exporter, you can capture all the value and then you earn more profit.”

More profit, in this case, means the minimum wage. “Hardly any brand pays minimum wage to the artisans,” says Ruaab SEWA’s chief operations officer, Rupa, who goes by just her first name within the organization. (Many members of SEWA use their first names with the suffix behen or ben, which mean “sister” in Hindi.) ”It shows in their books, but they are not actually paying that much.” She says sometimes Ruaab SEWA accepts lower wages if its workers are desperately in need of the work.

Before joining the program, Malti made bindis, the small, decorative circles worn on the forehead by many Hindu women. She had no training in embroidery or garment work, but the increased pay SEWA offered was enough for her to want to learn. Currently, her typical day starts at dawn. By 10am, she finishes her household chores. She then starts working on the clothes provided to her by SEWA. She sits on the double bed in her room almost the whole day, except during the hour she takes for lunch. Her day finally ends between 7 and 8pm.

“Compared to bindis, I now make a lot more money,” she tells Quartz. “I earn between Rs100 ($1.49) and Rs150 ($2.23) every day.” In a good month, she earns $75, but in a slow month it can be just $45. No matter what, she tries to put away about $3 a month in savings.

On the margins

While the income from work such as attaching sequins or sewing shirts helps, it’s rarely anywhere close to a living wage. Like much of the poorly paid work in developing economies, it’s indispensable, yet still insufficient. The supply of work can also be erratic, and during slow periods can fall to just a few hours a week.

“Home-based production by women, if there are other sources of income, may be what could help that household rise above the poverty level,” says Martha Chen, a lecturer in public policy at Harvard’s Kennedy School and co-founder of WIEGO. ”But home-based as the main source of income is never going to do it. There just aren’t enough earnings for a woman to work her way out of poverty.”

Referring to WIEGO’s longitudinal study, she adds, “And this is where it’s really a tough world out there: We did a 10-city study of three groups of informal workers: home-based, street vendors, and waste pickers. The home-based workers on average earned one-third of what the waste pickers earned.”

WIEGO recorded piece rates for a subcontracted homeworker in Ahmedabad of 10 rupees per shirt, at an output of about 10 per day, which translates to daily earnings around $1.80. In Lahore, the wages weren’t any better. A homeworker might earn $1.50 to make 24 shirts, while a garment worker in a factory could make roughly twice that for an eight-hour day. WIEGO also found that in Bangkok, a self-employed garment worker made on average about $28 for a seven-hour day, while a subcontracted garment worker made just $9 on average, and worked nine hours.

Homeworkers are also particularly vulnerable to exploitation. Because they exist outside the formal manufacturing system, there’s no one overseeing the conditions they work in or how they’re treated. Being poor, they’re often less educated and don’t typically organize into unions.

Female homeworkers tend to be in an especially weak position. In large areas of northern India, Pakistan, and Bangladesh, for instance, many women work from their homes because it’s still taboo for them to venture out in public unaccompanied by a man. They may have little idea of what a fair wage is, or how to demand better pay, or how to protest when they’re paid late—a common complaint among homeworkers.

In his experience, Kumar says if women do try to negotiate, the contractor may simply take the work elsewhere. People need the money; there is always someone else willing to take the job. The Solidarity Center report described the situation as creating “a plentiful pool of ‘cheap’ female labour.”

At the very worst, homeworkers and other subcontracted workers can face conditions akin to slavery. A report (doc) released in November by the UN Human Rights Office said that at the ends of these complex supply chains are instances of ”debt bondage, forced labour or the worst forms of child labour.” It named the clothing industry, particularly “home-based or small workshops in the informal economy,” as one of those especially prone to abuses.

An incentive for abuse

The difficulty in eradicating these problems is that using homeworkers is profitable. Both Chen and Kumar say factories generally like to rely on them when possible because it allows them to offload costs.

“The woman who is the home-based producer, she pays for the space, she pays for the equipment, she pays for the utilities, she buys the needles and thread and machine oil and whatever else is needed for production,” Chen says. ”The only thing she doesn’t pay the costs of are the raw materials and the design-marketing side of things.”

One notable expense is electricity. For a family that survives on just a few dollars a week, the cost of running an electric sewing machine all day can be significant.

Another serious problem is child labor. Since homeworkers are frequently poor, rarely have a steady flow of work, and get paid a piece rate, they have an incentive to get as many pieces done as possible when there is work. If children are in the house, they may be enlisted to help.

Nike faced a public-relations crisis in 2006 over its operations in Pakistan. The country produces more than 80% of the world’s match-grade soccer balls, and roughly 58% of the people making them are women homeworkers, by WIEGO’s estimate. When inspectors from rival Adidas discovered children at local homes in Pakistan stitching Nike balls, it threatened to embroil Nike in another child-labor scandal similar to the one it had faced a decade earlier. Nike had even been working with its Pakistani supplier to eliminate homework from its supply chain because of its links to child labor.

The global marketplace

The whole system, according to WIEGO, is driven largely by trade liberalization and an increasingly globalized economy. “Outsourcing of work to home-based workers and the associated lack of power of these workers are both inextricably linked to recent shifts in how global production is organized,” WIEGO stated in its longitudinal study.

It’s essentially an extension of global outsourcing. In much the way that fashion brands first outsourced work to Asian countries with cheap labor, freeing them of responsibility for the workers, factories in those countries have been outsourcing their manufacturing to homeworkers.

“It mirrors the macro picture of the garment industry,” Kumar says. “If company A has to place an order, the sourcing team takes costing from 10 or 15 different factories from five different countries. Whoever quotes the lowest price, the brand will go to that factory, that country. Similarly, the contractor: He will go to those homeworkers who are ready to work at a lower cost. It’s the same.”

For some companies, this system has proved highly profitable. Amancio Ortega, the owner of Zara, which uses an innovative approach to manufacturing combined with this outsourcing, briefly surpassed Bill Gates as the world’s richest person earlier this year.

But it’s worth noting that homeworkers themselves may not feel they’re being exploited. “The most common disadvantages pointed out were irregularity of work and low remuneration (piece rates), but there was no perception of being exploited,” the Solidarity Center report stated about the women interviewed. In need of income, most of the women wanted more work.

The way forward

There’s no single, clear solution to these problems. The system of price pressure and subcontracting that has developed over the past decades is a direct result of companies looking for the cheapest, fastest way possible to make their products. The goal also shouldn’t be to keep homeworkers out of supply chains, but rather to make sure they’re fairly treated and protected under the same laws as other workers. The first step is to bring them out of the shadows and acknowledge that they exist.

One attempt at a comprehensive solution was the International Labour Organization’s 1996 Home Work Convention, which seeks to ensure homeworkers are treated like other wage earners. But of the 186 member countries of the ILO, only a handful have ratified it.

Other efforts have focused on the relationship between workers and brands. The ETI’s homeworking project established guidelines for how retailers and their suppliers should handle homeworkers, while non-profit Nest helps home-based artisans connect with brands. One of its project was a collaboration a few years ago between home-based weavers in Kenya and The Elder Statesman, a high-end label that sells in stores such as Barneys New York.

Greg Chait, Elder Statesman’s founder, says the arrangement was successful all around. “We’ve figured out a way to be very meaningful to them financially,” he told Quartz. “It’s been very good for all parties every time we do something like this.”

But these are relatively small-scale fixes, focused on artisans rather than industrial homeworkers. Even Ruaab SEWA says it can’t do much for large brands because it doesn’t have a stitching unit to do work on that scale, though it does hope to open a factory at some point.

Arguably it’s the more traditional activities of trade unions such as Homenet and SEWA that can help. They educate workers on what practices are fair, advocate on their behalf, and can offer development programs, such as microfinance lending in SEWA’s case.

But most homeworkers aren’t in unions, and the reality is that, for them to be recognized, protected, and paid better, it’s going to take efforts from everyone involved, including governments, brands, and manufacturers.

It also requires something of consumers. It’s naive to expect the intense pricing competition driving this system to change anytime soon, but it arguably can’t change unless shoppers are willing to pay more for the work that makes possible many of the products they buy everyday.

One consequence of a globally distributed supply chain built on layers and layers of contractors is that we can lose sight of the people at the other end of it. Small details such as the buttons and beads on our clothing are reminders that they exist. It’s worth taking a moment to notice them, and to reflect on the price we implicitly put on their time and effort.

With reporting by Shelly Walia in Delhi, India.